PROJECT BLACK SPOTS

PROJECT

Syringe Improvement

INDUSTRY SECTOR

PHARMACEUTICAL SUPPLIER

Luer-lock syringe barrels for the filling of pre-filled syringe applications of various lifesaving medicines were sourced from an international recognized manufacturer in Germany. These syringe barrels are processed at multiple facilities during production operations.

“Black Spots” were detected in the syringe tip with varying distribution on several batches.

Though this flaw was initially characterized as “Minor” because of the lack of patient safety impact, the pharmaceutical manufacturer implemented a 100% pre-use visual inspection of all syringe barrels received. This inspection was to remain in place until such time as corrective actions could be proven effective at reducing the occurrence of the black spot flaw to acceptable levels.

OUR APPROACH

The project “Black Spots” was conducted using the 5 phase Six Sigma method DMAIC (Define, Measure, Analyze, Improve, Control).

Describe the business pain and the full arguments for the project. At the end of the define phase a completed project charter is to be presented to the project sponsor for approval.

Collect and test information/data. Various analytical tools are used here to collect information and to test the quality of this information. If not enough information is collected, this increases the probability of a beta error (saying nothing is wrong, when in fact there is). If the information is of poor quality, this increases the probability of an alpha error (saying there is something wrong when in fact there is not).

Make a decision. Based on the information collected in the measure phase, decisions are made here as to what is causing the business pain described in the define phase.

Fix/improve the process. Various possible solutions are analyzed and tested to confirm elimination of the business pain.

Stable and predictable process. PDCA (Plan-Do-Check-Act) process controls are placed within the process to react on leading indicators (found during the analyze phase) which have a direct impact on the business pain (lagging indicator).

THE RESULTS

ROOT CAUSE

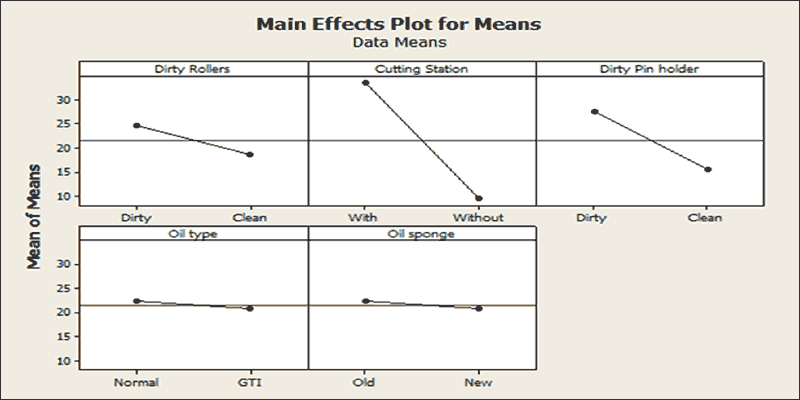

After having conducted a Tugushi Design of Experiment, it was confirmed that the black spots are formed by combining opportunity and introduction of a contaminate.

The opportunity, air bubbles and rough surface in and on the syringe tip, are inherent to the syringe manufacturing process by: heating up, roll forming, and cutting the glass.

When these tiny air bubbles and rough surfaces come in contact with a surface contaminant, such as the lubricated on forming rolls and lure cone forming station, the contaminant is then transferred to the syringe tip. The contaminant, oil lubricant, is also inherent to the syringe manufacturing process. Oil lubricant must be used on forming rollers to avoid glass sticking to rollers.

To reduce the probability of providing the opportunity, the following improvements have been made:

Proper flame adjustment (heat and position of flame)

- Position (up-down, left-right, front-back)

- Heat (gas-oxygen ratio)

Cutting station

- Exchanging and sharpening actual cutting wheel at predetermined intervals

To reduce the probability of providing the contaminant, the following improvements have been made:

Cleaning and maintaining roll forming station at predetermined intervals

- Exchanging oil lubricant sponge

- Removing built-up oil lubricant deposits on forming wheels

Cleaning and maintaining lure cone forming station at predetermined intervals

- Exchanging forming needle

- Removing built-up oil lubricant deposits on forming needle holder

Ensuring proper and clean oil lubricant is used

THE FINAL RESULTS

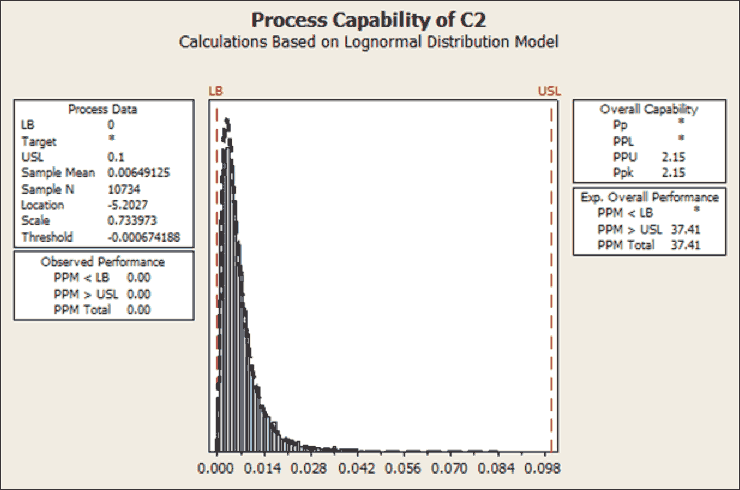

From an initial 100’000 ppm defect rate (10%), a goal of 100 ppm’s (0.001%) defect rate was set. Final process capability of 38 ppm’s (0.00038%) was accomplished.

“In an effort to ensure patient safety and meeting health authority requirements, this matter was costing us millions of Swiss francs a month. SECORA was able to contain, pin point, resolve, and eliminate this issue without interfering with operations. The structured way and data driven decisions SECORA used to remove this problem convinced the FDA the issue was resolved, which allowed us to continue to supply the market and of course the ultimate safety to patients.”

Project Sponsor

OTHER CASE STUDIES

Please note: some project details may not be available, due to confidentiality agreements with our clients.

Automotive

The project’s purpose was to reduce rail car demurrage for the client’s company. Rail cars are used to move material (parts) from suppliers to the automotive assembly plant and supporting facilities. Demurrages are tariff charges assessed for detaining freight cars beyond their specified time limit. Demurrage charges are billed to the assembly plant from the railroad when rail cars are held at the assembly plant or supporting facilities beyond the contracted amount of time.

End-to-End preparation of Tax Returns

A Kaizen (Continuous improvement) initiation project was led by SECORA from September 2007 until December 2007 at one of the ‘big 4’ accounting companies in Sydney, Australia. The project reviewed the firm’s process for the completion of international tax returns.

Laser Welding (Automotive)

A Tier 1 European automotive supplier had major issues on a newly launched product: Failure to meet customer volume requirements; Failure to meet customer quality requirements; Massive cost overrun. Using the SLIM (Lean) Methodology SECORA helped the client to solve its most prominent operational effectiveness issues and reduce internal manufacturing cost to below the original target costing, without capital investment or design change.

Logistics

SECORA was engaged by a major logistics organisation to review and optimize the business processes surrounding the management of third party contractors within its IT Department.