THE RESULTS

ROOT CAUSE

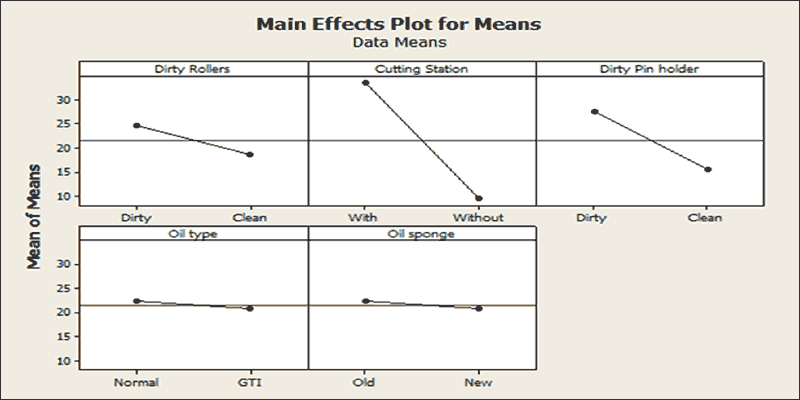

After having conducted a Tugushi Design of Experiment, it was confirmed that the black spots are formed by combining opportunity and introduction of a contaminate.

The opportunity, air bubbles and rough surface in and on the syringe tip, are inherent to the syringe manufacturing process by: heating up, roll forming, and cutting the glass.

When these tiny air bubbles and rough surfaces come in contact with a surface contaminant, such as the lubricated on forming rolls and lure cone forming station, the contaminant is then transferred to the syringe tip. The contaminant, oil lubricant, is also inherent to the syringe manufacturing process. Oil lubricant must be used on forming rollers to avoid glass sticking to rollers.

To reduce the probability of providing the opportunity, the following improvements have been made:

Proper flame adjustment (heat and position of flame)

- Position (up-down, left-right, front-back)

- Heat (gas-oxygen ratio)

Cutting station

- Exchanging and sharpening actual cutting wheel at predetermined intervals

To reduce the probability of providing the contaminant, the following improvements have been made:

Cleaning and maintaining roll forming station at predetermined intervals

- Exchanging oil lubricant sponge

- Removing built-up oil lubricant deposits on forming wheels

Cleaning and maintaining lure cone forming station at predetermined intervals

- Exchanging forming needle

- Removing built-up oil lubricant deposits on forming needle holder

Ensuring proper and clean oil lubricant is used